DPS BoilerMaster DPS BoilerMasterBoiler

Fed Instantaneous Water Heater |

|

DPS BoilerMaster DPS BoilerMasterBoiler

Fed Instantaneous Water Heater |

|

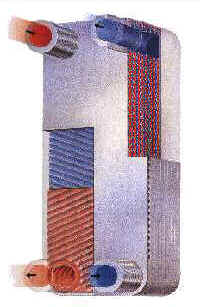

The DPS BoilerMaster is a self-contained, pre-plumbed and pre-wired, unit designed to provide mains pressure hot water from a boiler circuit, without the need for water storage. Ideal for use on district heating and central boiler applications. Space Saving 357mm wide x

390mm high x 177mm deep |

||

|

||

The BoilerMaster extracts

heat from the boiler circuit and uses this to heat up mains cold water, as follows:

The Y-Pattern Strainer protects the Flow Switch from particles of grit in the cold mains water supply. |

Numerous

heat transfer plates within the heat exchanger keep the primary boiler water completely

separate from the mains water, allowing each to operate independently at up to 5 bar

pressure. The heat exchangers themselves are tested to 72 bar pressure. Numerous

heat transfer plates within the heat exchanger keep the primary boiler water completely

separate from the mains water, allowing each to operate independently at up to 5 bar

pressure. The heat exchangers themselves are tested to 72 bar pressure.The BoilerMaster can deliver hot water continuously at a rate determined by the input from the boiler, up to a maximum heat transfer rate in the region of 100kW, equivalent to over 30 litres per minute of domestic hot water, providing the boiler can supply the heat to all units operating at once. It is important to understand that although a single BoilerMaster can easily supply two outlets simultaneously, is uses the energy generated by the boiler system to heat that water. If, for example, a block of flats are fitted with BoilerMasters, and 3 outlets are each supplying 18 litres per minute to bath taps then this will require a boiler output of 135kW (450,000 Btus/h). Careful consideration should be given to the maximum number of outlets that will be open at peak demand, to ensure the boiler is big enough to heat this water, and pipes sizes and water pressures are large enough to deliver this water. If a boiler large enough is not feasible, then some form of storage will be required to even out the demand. Using centralised heat storage in conjunction with instantaneous water generation in flats overcomes the need for domestic hot water distribution to each flat, and as such may reduce Legionella risk. The BoilerMaster is fully assembled, wired and tested to ensure all components are working and that all pipework is leak free. It comes in an attractive white metal casing, with three keyholes provided for easy wall mounting. Variations on the BoilerMaster include the following

options (larger casings may be required):

|