|

|

Telephone

01372 803 675 |

|||

|

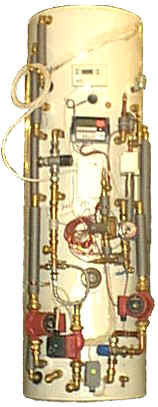

Customers requirements: A hot water and central heating system, to supply multiple dwellings from a central boiler house. No external overflow or warning pipes

desired. The system should be completely 'plug-and-play' with all

components factory fitted and tested, and all controls pre-balanced and

locked. Controls to include differential pressure control, complete

isolation of each system from the primaries, and integral class C heat meters. |

|||||

The system presented some additional challenges. A plate heat exchanger must be used to isolate the boiler primaries from the hot water and central heating system. This ensures no cross-contamination of either system, as well as allowing each heating system to be sealed with corrosion inhibitor. To improve boiler efficiencies the return temperatures should be kept as low as possible, in turn requiring the use of some system modulation. The class C heat meter was a new one on us, however. The unit comprises of a heat meter, a flow meter, and two temperature sensors - one in the boiler flow, and one in the return. The heat meter calculates information regarding heat energy input from the primaries, which is sent to a central data store, a sent from their to council offices by modem, allowing the residents to be appropriately billed. |

|||||

The use of our patented Stowaway Heat Bank Thermal Store took care of the requirement for no overflow. The system is manually filled and sealed from atmosphere to prevent water loss. An integral overfill chamber is built in to prevent spills from overfilling, and a low level indicator light shows when water is getting low should any be lost by draining or changing radiators. Our patented GX recovery system, combined with a plate heat exchanger and zone valve, is used for the primary controls for getting heat into the store, while keeping return temperatures low. Additional requirements were taken care of by fitting the appropriate heat meter, flow meter, differential pressure control, temperature sensors, and pressure sensors. A plate heat exchanger is used to provide mains pressure hot water, at very generous flow rates, and removes the need for any cold storage. The entire system only requires 6 connections, all push-fit using Tectite brass fittings: 1. Primary In 15mm

Wiring at installation comprises of connection to the mains supply, using 3m cable provided, a room thermostat, and the data link. |

|||||

CASE

STUDY Slough Borough Council

CASE

STUDY Slough Borough Council Cupboard

entrances were only 500mm wide making the use of 480mm diameter units necessary.

Cupboard

entrances were only 500mm wide making the use of 480mm diameter units necessary.