GXV Heat Bank Thermal Store

GXV Heat Bank Thermal Store

The GX and GXV Heat Bank Thermal Stores were designed with the following goals in mind:

1. High performance

Fill a bath with hot water at a flow rate of 20 to 25 litres per minute.

Full recovery should be made within 30 minutes.

2. Energy efficient

The unit should take full advantage of condensing boiler technology

The boiler should not cycle during recovery.

Standing heat losses should be low.

3. Easy to install

The units should be able to be installed by the average plumber.

There should be no aspects of the installation that require expert knowledge.

The unit should fit into small cupboard spaces, such as under a worktop.

There should be no need for system balancing.

There should be no need for any wiring to be made by the installer, other than a mains electrical supply to the unit and basic wiring to the boiler.

4. Reliability

All components should be reliable, requiring the minimum of maintenance.

The cylinder itself should be immune to the effects of limescale.

5. Easy to maintain

Should any maintenance work be required, all components should be accessible and simple to replace.

In summary, we aimed to produce a complete package that would ensure the trouble free installation of a modern, highly efficient, hot water heating system.

With the development of the GX and GXV units we have successfully achieved this goal.

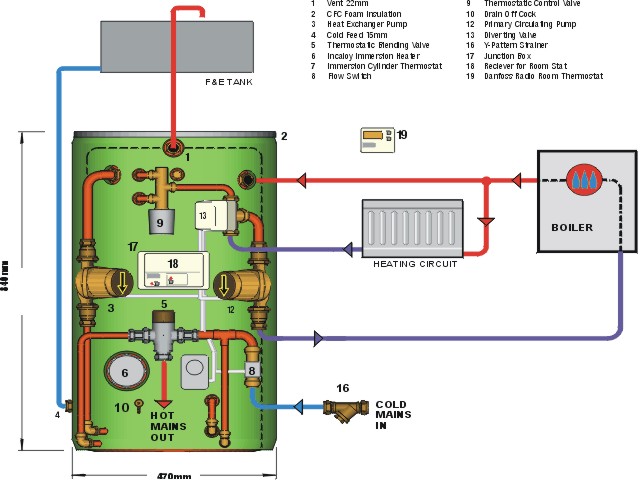

![]() The GXV supplies mains

hot water, removes the need for a cold water storage tank and pipework run in loft spaces.

The GXV supplies mains

hot water, removes the need for a cold water storage tank and pipework run in loft spaces.

![]() The primary pump,

three-port valve, cylinder thermostat, domestic blending valve, and wiring centre are

securely factory fitted and wired, making site installation very simple.

The primary pump,

three-port valve, cylinder thermostat, domestic blending valve, and wiring centre are

securely factory fitted and wired, making site installation very simple.

![]() No sealed system

controls on cylinder since it is vented and no domestic water is stored.

No sealed system

controls on cylinder since it is vented and no domestic water is stored.

![]() Removes the need to

balance the boiler flow.

Removes the need to

balance the boiler flow.

![]() Installer only needs to

connect to the boiler, radiators, feed & expansion tank, and mains supply.

Installer only needs to

connect to the boiler, radiators, feed & expansion tank, and mains supply.

![]() Controls centralised and easy to access for

servicing.

Controls centralised and easy to access for

servicing.

![]() daptable

daptable

![]() Designed to operate with

virtually any vented gas boiler.

Designed to operate with

virtually any vented gas boiler.

![]() Removes the need to

balance the boiler flow.

Removes the need to

balance the boiler flow.

![]() Small unit dimensions,

only 850mm tall, allows installation in small cupboards or under worktops.

Small unit dimensions,

only 850mm tall, allows installation in small cupboards or under worktops.

![]() High hot water flow

rates, up to 30 litres/minute, permitting supply to multiple outlets.

High hot water flow

rates, up to 30 litres/minute, permitting supply to multiple outlets.

![]() Large volumes of hot

water, up to 170 litres @ 43°C, suitable for use in larger houses.

Large volumes of hot

water, up to 170 litres @ 43°C, suitable for use in larger houses.

![]() High hot water pressures, for mains supply

up to 6 bar, for use in multi-storey constructions.

High hot water pressures, for mains supply

up to 6 bar, for use in multi-storey constructions.

![]() ew products for water

conservation

ew products for water

conservation

![]() Fast delivery of hot

water to taps reduces water loss while waiting for the supply to reach a usable

temperature.

Fast delivery of hot

water to taps reduces water loss while waiting for the supply to reach a usable

temperature.

![]() High pressure supply

allows use of smaller bore hot water pipework, further reducing the volume of water drawn

off until the supply reaches a usable temperature.

High pressure supply

allows use of smaller bore hot water pipework, further reducing the volume of water drawn

off until the supply reaches a usable temperature.

![]() Very Rapid recovery avoids water waste

because a bath is not hot enough to use.

Very Rapid recovery avoids water waste

because a bath is not hot enough to use.

![]() nnovative energy efficient hot

water supply & space heating

nnovative energy efficient hot

water supply & space heating

![]() Control of boiler return

temperatures allows maximum efficiency to be gained from condensing boilers. Boiler made

to operate in condensing mode as long as possible during heat-up.

Control of boiler return

temperatures allows maximum efficiency to be gained from condensing boilers. Boiler made

to operate in condensing mode as long as possible during heat-up.

![]() Significantly reduces

boiler cycling.

Significantly reduces

boiler cycling.

![]() CFC Free Insulation

locks away stored heat.

CFC Free Insulation

locks away stored heat.

![]() Low storage volume, 80 litres, reduces

standing heat losses.

Low storage volume, 80 litres, reduces

standing heat losses.

![]() he elimination of lead in

drinking water

he elimination of lead in

drinking water

![]() All pipework components are made from

copper, brass or stainless steel.

All pipework components are made from

copper, brass or stainless steel.

![]() ssuredly safe electrical/gas

equipment installations

ssuredly safe electrical/gas

equipment installations

![]() Fully vented primary

system and storage cylinder.

Fully vented primary

system and storage cylinder.

![]() Primary system controls

factory fitted and wired to high quality standards.

Primary system controls

factory fitted and wired to high quality standards.

![]() Fused wiring centre.

Fused wiring centre.

![]() Simple step by step installation procedure

helps prevent mistakes.

Simple step by step installation procedure

helps prevent mistakes.

![]() horoughly competent, well

educated, trained, responsible professionals

horoughly competent, well

educated, trained, responsible professionals

![]() All component suppliers have been selected

with service backup a primary concern, as well as their ability to provide high quality

training. Factory training courses if required.

All component suppliers have been selected

with service backup a primary concern, as well as their ability to provide high quality

training. Factory training courses if required.

![]() ntroduction of performance

standards for new technology

ntroduction of performance

standards for new technology

![]() The high level of performance provided by

the GXV will set new standards.

The high level of performance provided by

the GXV will set new standards.

![]() riginal designs for self-cleansing

riginal designs for self-cleansing

![]() Domestic plate heat exchanger designed to be

self-cleaning at typical supply flow rates.

Domestic plate heat exchanger designed to be

self-cleaning at typical supply flow rates.

![]() ovel & energy efficient

ovel & energy efficient

![]() A completely new approach to system design

with energy efficiency the main objective.

A completely new approach to system design

with energy efficiency the main objective.

High performance

The GXV Heat Bank Thermal Store provides up to 30 litres per minute of mains pressure hot water using our latest high efficiency plate heat exchanger technology. The use of a plate heat exchanger keeps the stored water completely separate from the mains water supply. This allows the use of a vented storage cylinder, and removing the need for cold water storage.

The hot water supply is not stored and may therefore be used for drinking, without the dangers of Legionnaire's.

The small size of the unit, typically 80 litres, ensures rapid recovery from a standard boiler. Following a bath, a 12kW (40,000 Btu) boiler can recover the entire store within 20 minutes.

The greatest problem that faced us when designing the GXV was obtaining the large volumes of hot water that were demanded from such a small unit. After a year of experimenting with various systems, we developed a way to extract nearly 100% of the stored heat, and at the same time ensure that 100% of the boiler output went directly to the taps.

This combination of stored heat and boiler input finally allowed us to fill a bath at 25 litres per minute to 43°C, with surplus stored heat left in the store. In factory tests the GXV provided 170 litres at 45°C, and at an average flow rate of 25 litres per minute.

The methods we used to achieve this also provided hot water within 3 minutes of cold start.

Energy Efficiency

A benefit of the patented method used to recover the stored water, is the ability of the GXV to automatically control the return temperature to the boiler.

To achieve the maximum efficiency from a condensing boiler the return to the boiler must be kept below 55°C. The GXV will hold the return to the boiler at a pre-set temperature, typically 53°C, until the entire store has been heated to this temperature. During this recovery, the boiler will be continually in condensing mode and will not cycle.

Energy efficiency is further increased as a result of the small capacity of the unit. With such a small surface area heat losses are minimised. CFC free factory foam insulation, combined with pipe insulation, keeps stored heat locked away.

Water and heat waste is reduced by the extremely fast response times to taps. When a tap is opened, the hot water supply temperature jumps nearly instantaneously to the set output temperature on the thermostatic blending valve, so that the user does not have to run off water waiting for the temperature to climb to a suitable level. The fact that the water is at mains pressures also enable the use of small bore pipework, further reducing water waste.

To reduce energy loss through central heating, the units make use of a programmable room thermostat that provides accurate control of room temperatures, allowing different temperatures to be set for different times.

For example, night setback setting can be easily programmed. This method provides more precise control of the central heating load, thereby increasing the overall system efficiency.

![]() Solar Applications: It should also be noted, that a solar version of the

GXV has also been developed. The small storage size required with a GXV unit for domestic

use make it ideal for solar applications. A typical 250 litre domestic solar cylinder

requires the gas boiler to heat up around 115 litres of water for domestic use, leaving

130 litres dedicated to solar heating. A similar sized GXV unit, requiring only 80 litres

for domestic use, would provide 170 litres for solar use. This additional solar storage

increases the gains from solar panels and the energy efficiency of the entire system.

Solar Applications: It should also be noted, that a solar version of the

GXV has also been developed. The small storage size required with a GXV unit for domestic

use make it ideal for solar applications. A typical 250 litre domestic solar cylinder

requires the gas boiler to heat up around 115 litres of water for domestic use, leaving

130 litres dedicated to solar heating. A similar sized GXV unit, requiring only 80 litres

for domestic use, would provide 170 litres for solar use. This additional solar storage

increases the gains from solar panels and the energy efficiency of the entire system.

Easy to Install

At an early stage in the design process, it was realised that the only way to ensure correct rapid installation of all system controls is to supply the installer with a fully pre-fabricated system.

Any system components that have to be fitted by the installer, because they cannot be pre-fabricated, should be simple to connect, requiring the minimum of additional on-site work.

With all components factory fitted, wired, and tested, the local authority could then rest easy in the knowledge that the hot water and heating systems in properties fitted with a GXV had been put together properly.

In addition to the Heat Bank Thermal Store controls, the GXV Heat Bank Thermal Store is factory fitted with all the usual domestic hot water and heating system controls, as follows:

Domestic Blending Valve

Primary Circulating Pump

Motorised Three Port Valve

Cylinder Thermostat

Wiring Centre

The only part of the control system that cannot be

factory wired is the room thermostat. We were able to overcome this by using a Danfoss

TP5E RF room thermostat and RX1 digital radio receiver. The room thermostat communicates

with the receiver, fitted and wired to the Heat Bank Thermal Store, using a digital radio signal. The

room thermostat runs for two years of two standard AA batteries, requires absolutely no

wiring, and can be easy positioned (or re-positioned) to suit.

The only part of the control system that cannot be

factory wired is the room thermostat. We were able to overcome this by using a Danfoss

TP5E RF room thermostat and RX1 digital radio receiver. The room thermostat communicates

with the receiver, fitted and wired to the Heat Bank Thermal Store, using a digital radio signal. The

room thermostat runs for two years of two standard AA batteries, requires absolutely no

wiring, and can be easy positioned (or re-positioned) to suit.

The installer is now faced with a very simple installation procedure.

Pipework connections:

![]() Cold mains water supply

Cold mains water supply

![]() Domestic hot water supply to taps

Domestic hot water supply to taps

![]() Return from radiator circuit

Return from radiator circuit

![]() Flow to boiler

Flow to boiler

![]() Return from boiler

Return from boiler

![]() Cold Feed & Vent

Cold Feed & Vent

Electrical connections:

![]() Mains electrical supply to Heat Bank Thermal Store

wiring centre

Mains electrical supply to Heat Bank Thermal Store

wiring centre

![]() Boiler supply from Heat Bank Thermal Store wiring centre

Boiler supply from Heat Bank Thermal Store wiring centre

System Balancing:

The way that the GXV unit operates also removes the need for a balancing valve between the boiler and the store.

System Adjustment:

All system components are factory pre-set to work with a typical domestic central heating installation. The only controls that may need adjusting are:

The GX Heat Bank Thermal Store for Sealed Systems

To provide greater flexibility in design and installation, we developed along-side the GXV, the GX Heat Bank Thermal Store for a sealed systems.

Where the installation will not allow the fitting of an F&E tank, the GX overcomes the problem by the use of a built in expansion vessel. The entire GX and heating system is pressurised, and no separate F&E tank is required. The GX is fitted with all the usual sealed system controls including:

Expansion Vessel

Pressure Relief Valve

Pressure Gauge

Overheat Thermostat

Filling Loop

Reliability

Any hot water or heating system is only as reliable as its individual components. That is why we have made sure that every component used in the GXV has been tried and tested to work in the field.

All assembled pipework is made to the highest standard using high quality fittings and jointing compounds to ensure leak free commissioning.

The cylinders themselves contain primary water, and so are protected against scale. A corrosion / scale inhibitor may be added to the store to provide added protection to the complete system.

Easy to maintain

One of the greatest problems that service engineers face is the inaccessibility of controls, preventing them from being easily serviced.

We have therefore made it a high priority, in designing the GXV unit, to position all components where a service engineer can be certain to reach them.

To make sure of this we fully serviced every component on the unit ourselves. Whenever we came across a potential situation, we repositioned the necessary components to ensure that it was overcome.

As a further check we asked an installer to service the various components. Any suggestions that were put forward to make servicing easier were implemented in the design.

Finally, full maintenance instructions, including such information as the system wiring diagram and fault finding chart, will be supplied with each unit.

Bosses, pipes, and controls are clearly labeled to assist with the installation of external pipework connections.

GXV Demonstration

During a demonstration conducted using a GXV Heat Bank Thermal Store in conjunction with the Vaillant VU186EH condensing boiler, the following procedure was followed, and readings taken:

The boiler was fired and left to fully heat up the stored water.

The hot water outlet into the bath was fully opened.

120 litres was drawn at an average of 50°C and an average flow rate of 25 litres per minute.

Without pause, a further 50 litres was drawn, to make a total of 170 litres of water at 45°C.

The hot water outlet was closed and the system left for only 3 minutes to recover.

The hot water outlet into the bath was then opened again.

A further 15 litres of 45°C water was drawn – sufficient for a basin or sink.

The hot water outlet was closed and the GXV Heat Bank Thermal Store left for 23 minutes to recover.

The hot water outlet into the bath was again opened.

A further 160 litres at 45°C was drawn off.

The entire test was then repeated with very similar results.

See for yourself...

If the GXV sounds too good to be true, then please come and see one in operation at our showroom in Epsom, Surrey. We have the ability to simulate various installation conditions and patterns of use allowing us to demonstrate how our systems will work with your proposed installation.

We have a number of other systems on display, including an operating Solar Heat Bank Thermal Store connected to panels on our roof.

To arrange a visit, please phone us on 01372 803675