- The primary flow rate is regulated to keep return temperatures low., modulating down to zero when there is

no demand.

- Very quick recovery of the store (boiler system permitting).

- Boiler input during draw-off will greatly increase the volumes of water

that can be obtained from a set store volume.

- It should be possible to fit all controls on to the unit, removing the

need for wall mounting the heat exchanger.

- There are no motorised valves used.

- There is no requirement for an overflow from each property.

- The water in the boiler circuit is isolated from both the store and the

radiator system, preventing contamination of the boiler pipework with

dirt/corrosion from radiator.

- Providing the store is recovered, the central heating will be brought up

to temperature very quickly by the use of stored heat. The primary

input will increase to accommodate this.

- The store will act as a very large air-separator, helping to speedily

remove air within the radiator circuit.

- Should the unit be fitted with an immersion heater, this can be used to

provide backup hot water and heating.

|

| A Mains Water Isolating Lever Valve must be fitted within the cylinder cupboard, in clear view and easily accessible. A Strainer (supplied loose) must also be fitted, down stream of the isolating valve, to protect the flow switch [4]. |

|

The Wiring Centre [42] is fitted with a neon which indicates when the unit needs topping-up. It is also fitted with a relay to prevent the Heat Exchanger Pump [3] from activating - there will be no hot water available until the unit is topped up manually, using the filling loop [8]. |

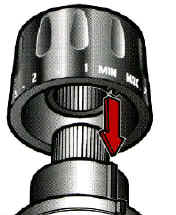

The unit is fitted with a Mixcall III Thermostatic Blending Valve, to control

the hot water temperature, and prevent scalding. The graph shows the pressure drop across the valve for various hot water flow rates. The unit is fitted with a Mixcall III Thermostatic Blending Valve, to control

the hot water temperature, and prevent scalding. The graph shows the pressure drop across the valve for various hot water flow rates.

The Valve is adjustable from 27°C to 67°C, and has a lockable

head. |

| The unit is fitted with an Integral Overflow Chamber [8], which traps small volumes of water discharged as a result of overfilling. Water in the chamber can be drained off via the Overfill Drain Cock [66]. The unit MUST be watched during filling as excessive overfilling will result in over-spill onto the floor. |

| The unit is fitted with one heat exchanger, capable of delivering 30 litres/minute @45°C (80°C

storage). The graphs shown the domestic hot water output that can be achieved for various storage temperatures.

|

| It is advised that the mains water is tested for hardness. In areas of hard water, we advise the use of a scale inhibitor. |

| It is important that SENTINEL X100 Inhibitor is used to protect the Heat Bank Thermal Store.

Use 1 litre per 100 litres of stored water. A suitable anti-freeze, such as X500, should also be added when there is a chance that the unit will be left filled and unheated in freezing conditions.

|